Mastering Manufacturing with Business Central: Executing Subcontracting in Production Orders

You've defined your routing. You've assigned the vendor. Now it's time to put subcontracting into action.

In this third installment of the Mastering Manufacturing with Business Central: Subcontracting blog series, we walk through the full subcontracting execution cycle—covering how production orders integrate with vendor services, how to use the subcontracting worksheet, and how actual costs flow back into your manufacturing ledger.

Step 1: Create a Production Order That Includes Subcontracting

In Business Central, you can begin with a firm planned production order for any item that includes an outsourced step. The routing you've configured will dictate which vendor service is required and when in the process it's performed.

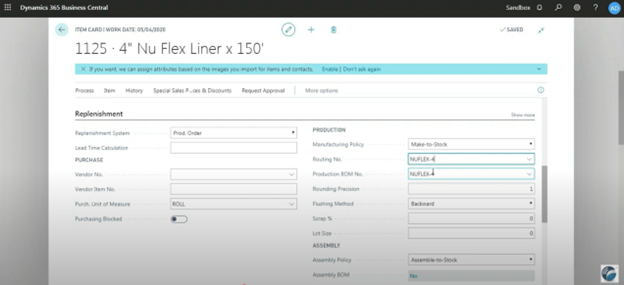

In this example, the team created a firm planned order for item 1125, with a quantity of 10 units.

Once the production order is created, you can immediately preview:

- BOM and material requirements

- Routing steps (including subcontracting)

- Cost estimates

Note: Subcontracting costs are calculated per the unit cost defined in the outsourced work centre. In this case, the vendor charges $2.00 per item painted.

Step 2: Release the Production Order

Before you can issue any subcontracting POs, the production order must be moved from Firm Planned to Released. Only released orders show up in the Subcontracting Worksheet.

Releasing the order signals that production is underway or ready to begin. It allows for:

- Component consumption

- Operation execution (internal and outsourced)

- PO creation for subcontracted steps

Once released, you can still view or override routing steps per order. For example, if you planned to outsource painting but choose to do it in-house due to vendor delay, you can manually change the work centre on the production order's routing.

Step 3: Access the Subcontracting Worksheet

The Subcontracting Worksheet evaluates all released production orders that include outsourced routing steps and identifies what vendor services need to be executed.

How to use it:

- Go to the Subcontracting Worksheet.

- Select Process > Calculate Subcontracting.

- Review the lines generated—each line represents a subcontracting requirement based on production order routing.

If multiple production orders are routed through the same vendor, Business Central will consolidate those into a single PO (when appropriate), making vendor management and processing far more efficient.

For example: 4 production orders needing painting from the same vendor will appear as one PO with 4 lines.

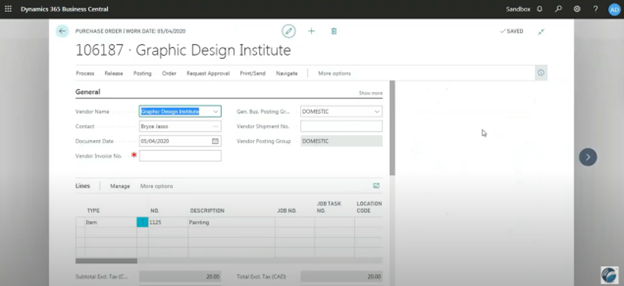

Step 4: Generate the Subcontracting Purchase Order

With the worksheet populated, you can execute the required action:

- Select the lines to process.

- Click Carry Out Action Message to generate the vendor PO.

The PO includes:

- Vendor details

- Reference to the production order

- Quantity (e.g., 10 units)

- Subcontracting charge ($20.00 total)

Tip: You can customize PO views using filters and dimensions to differentiate between regular and subcontracting purchase orders.

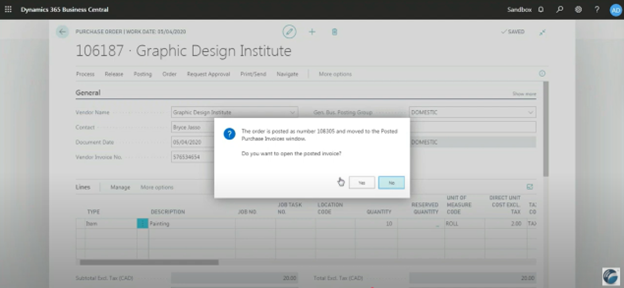

Step 5: Receive and Invoice the Subcontracting Service

After the vendor completes the outsourced task:

- Open the purchase order.

- Enter the received quantity.

- Post the receipt and invoice (together or separately).

The cost is now booked against the specific production order, ensuring true-to-life manufacturing cost tracking.

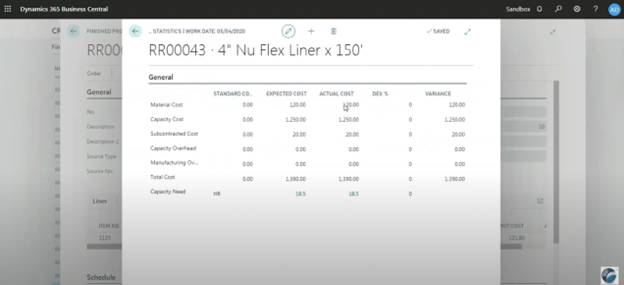

Step 6: Verify the Results in Production Statistics

Now that you've posted the subcontracted PO, head back to your Released Production Order to see the full picture:

In this case:

- $20 subcontracting cost

- $120 in material cost

- $1,200 in labour (assembly + QA)

- Total cost: $1,390.00

Because all components (except one) were auto-backflushed, and the routing times weren't edited, actuals aligned perfectly with planned values.

Step 7: Dive Into the Ledger Entries

To truly understand how Business Central tracks and applies subcontracting costs, explore:

1. Item Ledger Entries

2. Capacity Ledger Entries

This may seem unusual, but Business Central treats subcontracted service costs as capacity charges. It aligns with the logic that you're paying for an operation to be performed—just not within your own facility.

3. General Ledger Entries

Real-world tip: Posting groups ensure these entries reflect correctly in your financials. You can direct subcontracting costs to their own GL accounts for easier cost-of-goods-sold analysis.

Why This Matters

By executing subcontracting through production orders and the subcontracting worksheet, Business Central allows you to:

- Tie costs directly to the production process

- Track vendor work without losing inventory visibility

- Reduce manual steps through automated PO generation

- Capture granular production costs for better forecasting and margin tracking

Whether you occasionally outsource or it's a core part of your production strategy, Business Central ensures outsourced steps are handled as smoothly as your internal operations.

Watch the full video: Microsoft Dynamics 365 Business Central Manufacturing Series Part VI: Subcontracting

Contact WebSan Solutions to ensure your subcontracting operations are aligned with best practices in Business Central.