Mastering Manufacturing in Business Central: Variance Reporting and Key Metrics

Manufacturing is all about efficiency—making the right products, on time, and within budget. In Microsoft Dynamics 365 Business Central, reporting capabilities play a critical role in helping manufacturers understand their performance. Whether you're tracking costs, analyzing variances, or drilling into production orders, Business Central offers robust tools to keep your operations on track.

In this article, we'll explore how variance analysis works in Business Central and how you can use it to improve decision-making. This is part of our ongoing series on Business Central manufacturing. If you'd like to see the full demo in action, watch the complete video here → Dynamics 365 Business Central Manufacturing Series Part VIII: Reporting.

Why Variance Analysis Matters

When a product is manufactured, one of the first questions to ask is: Did we make it as efficiently as planned? This is where variance analysis comes in. Business Central allows you to compare expected costs with actual costs, identifying discrepancies in:

- Material usage

- Labour hours

- Machine time

- Quantity variances

These insights help manufacturers identify inefficiencies and take corrective action quickly.

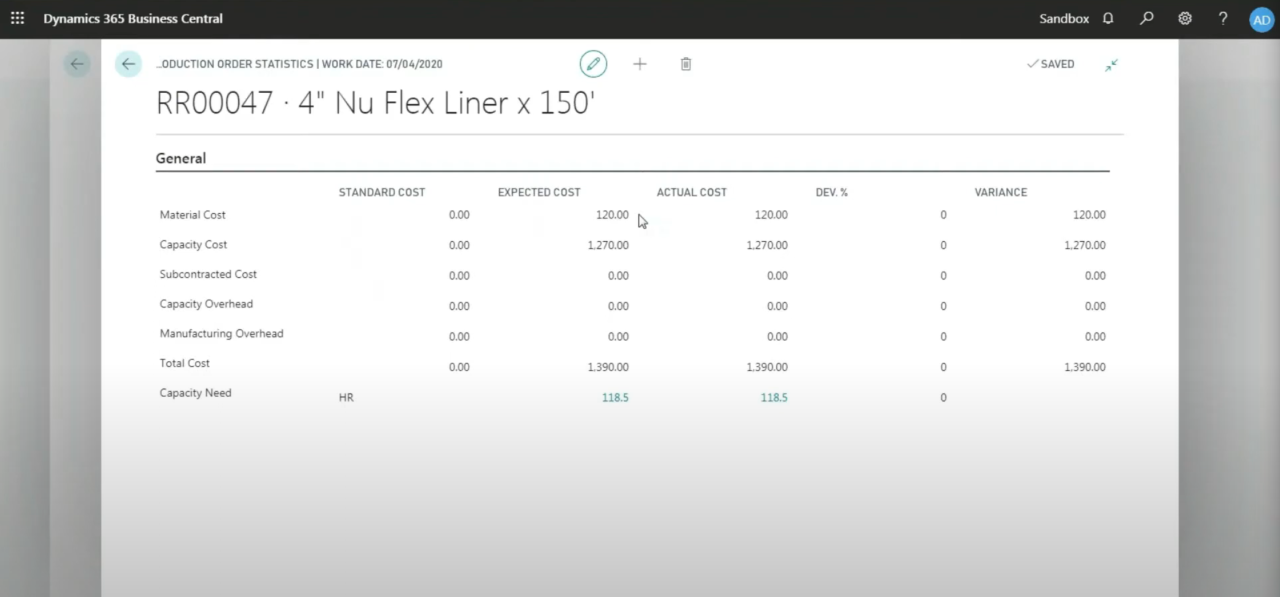

Where to Start: Production Order Statistics

The journey often begins at the production order level. Business Central makes it easy to analyze variances by opening the statistics view of a completed production order. Here, you can compare the expected cost against the actual cost for materials, labour, and overhead.

For example, in the demo, the statistics screen of a finished production order clearly shows material cost expectations and actual consumption. If any differences exist, they appear under the variance column.

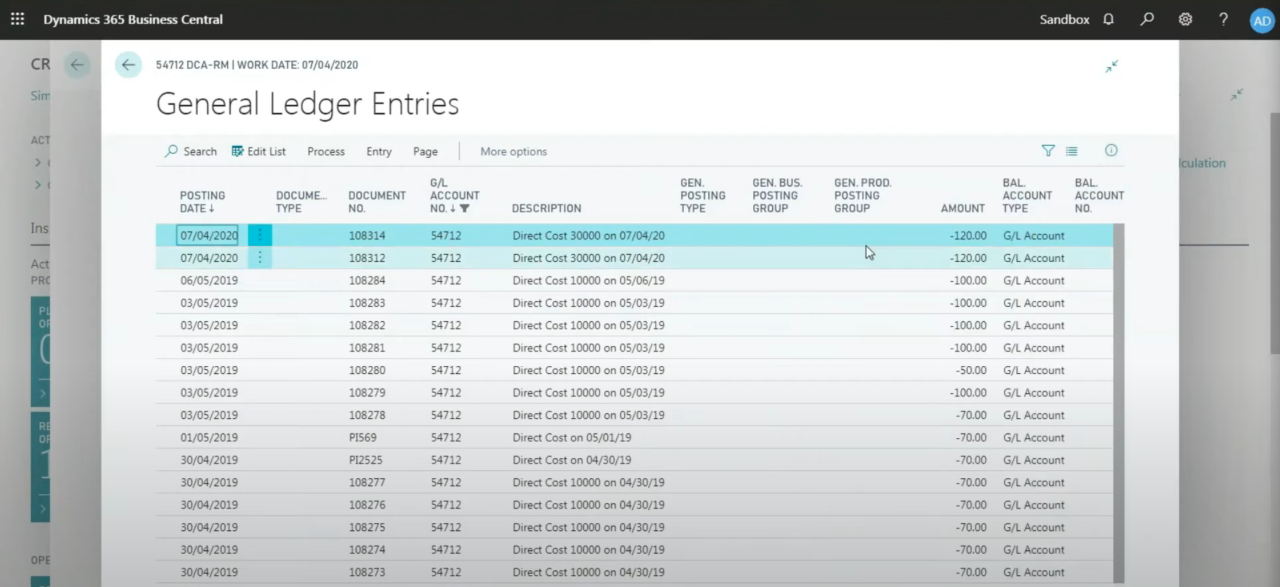

From the General Ledger to the Root Cause

Variance analysis doesn't stop at the order level. Often, the process begins in the General Ledger with a variance account balance. From there, you can navigate back to the originating transaction—whether it's a purchase order or a production order—providing full traceability.

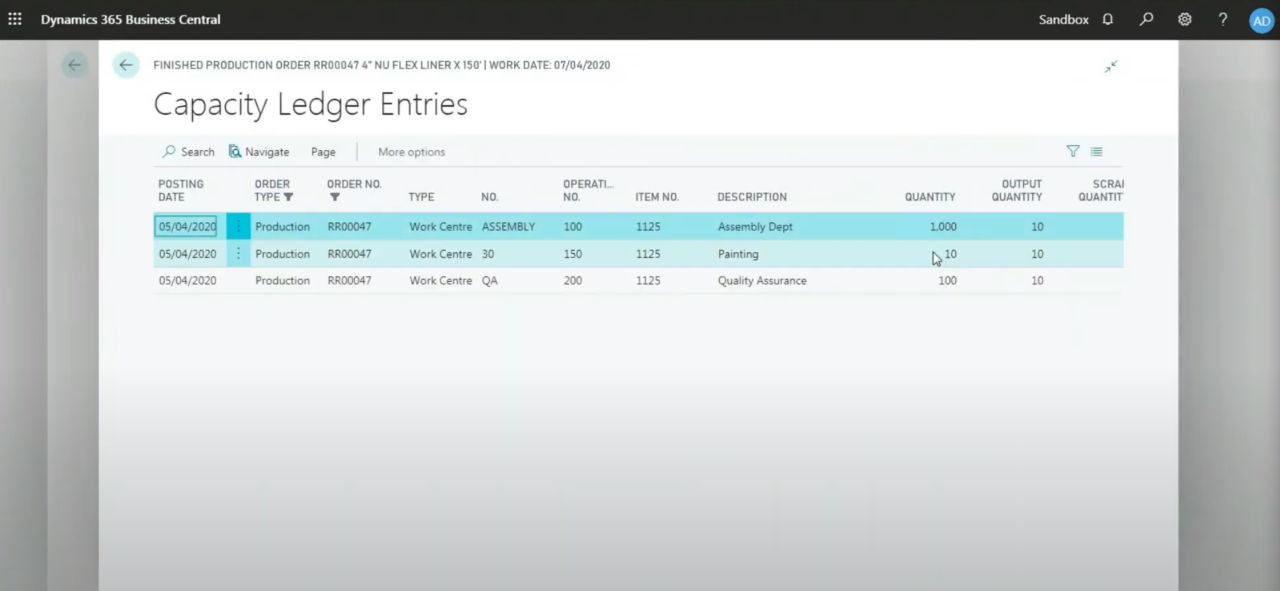

This end-to-end visibility is key. Starting with an account schedule, users can spot unusual variances in GL accounts and drill all the way back to see which transactions caused the issue. Business Central even allows navigation to item ledger entries and capacity ledger entries for granular detail.

Detailed Views: Item and Capacity Ledger Entries

For users who want deeper insights, Business Central provides item ledger entries to see material consumption and capacity ledger entries for labour and machine time. These entries reveal how closely actual performance aligns with the production plan—helping manufacturers uncover waste or inefficiencies.

Practical Tip

Even though it's tempting to review variances order by order, most businesses begin at the GL level. This approach provides a big-picture view and helps pinpoint problem areas before drilling into specific orders or components.

Why This Matters for Manufacturers

Variance reporting in Business Central is more than just a cost check. It's a tool for continuous improvement, helping manufacturers:

- Reduce material waste

- Optimize labour allocation

- Improve production planning accuracy

- Increase overall profitability

By understanding where and why variances occur, businesses can make informed decisions that lead to better performance on the shop floor.

Ready to Learn More?

For a deeper dive into Dynamics 365 Manufacturing reporting and to see these features in action, watch the full video: Watch the full webinar here